Vacuum Hose Coupling

To clean up chips created by the mill and lathe I use a small shop-vac. The hose is short so I have to hold the vac in one hand and the hose in the other to suck up chips. A pain. The only hose extension I found has a 2 1/4" fitting on the end that doesn't fit the vac tools. So an adapter is needed.

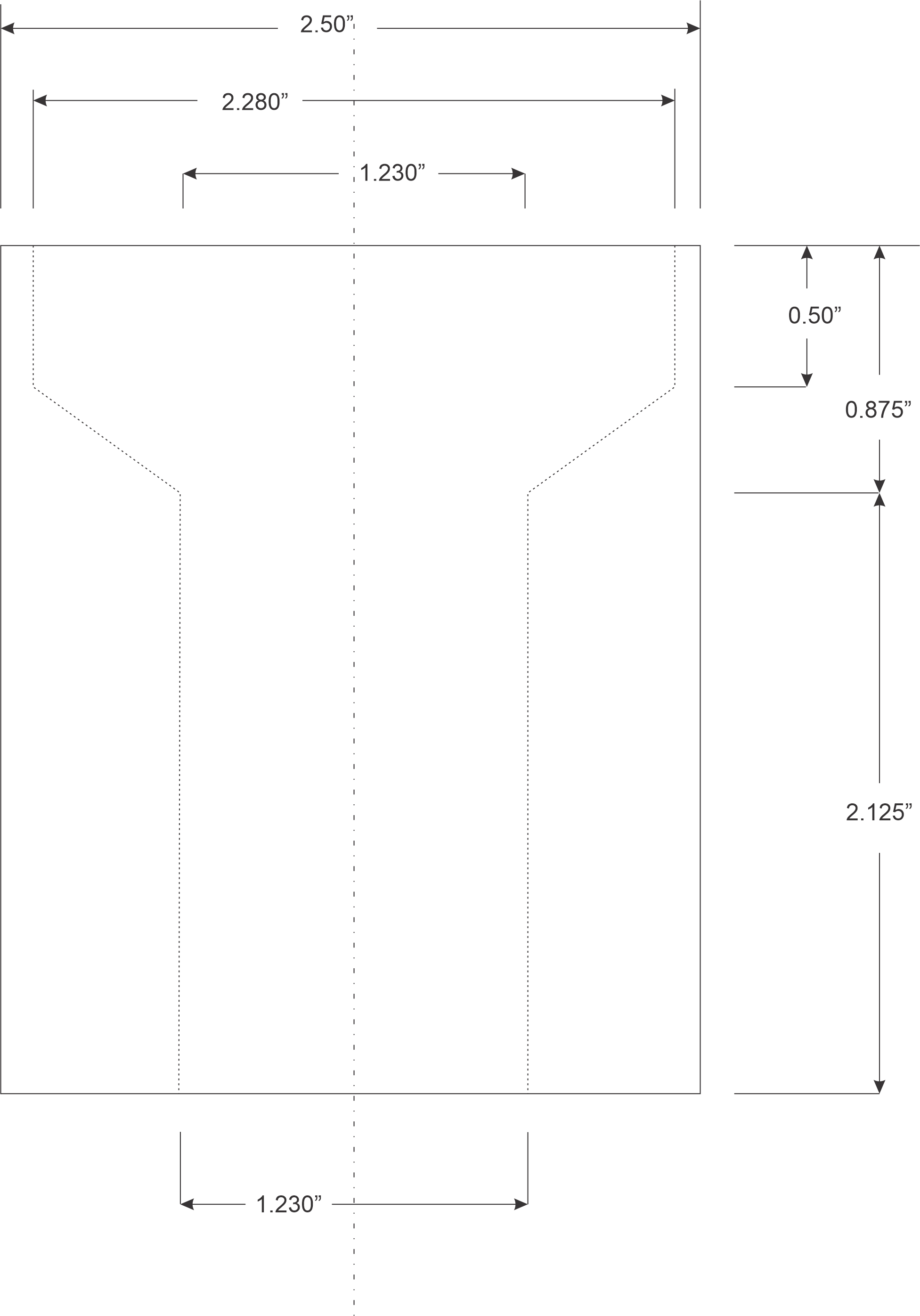

Using a 3" piece of 2 1/2" round Acetal stock I turned the following coupling on the lathe. The old hose connected to the shop-vac press fits into the small end and the large end of the new hose press fits into the large hole in the other end of the coupling.

The plan is to set the shop-vac on the floor, clip the coupling onto the equipment spill tray and have the new 6' hose to clean up chips. I installed an easily reachable wall switched and receptacle to plug the shop-vac into so I don't need to reach down to turn things on. Yep, old man getting lazy.

I center drilled then drilled a 1/2" hole down the center of the 3" piece of ACETAL. 1/2" is the largest bit I have and the hole is just large enough for the boring tool to fit into. The end of the shop-vac hose is there to collect as much of the shavings as possible. Static electricity made the little pieces go every which way - and stick!. The idea of the shop-vac is from a Blondihacks.com video.

When the small end was bored to size, the part was turned around and recentered with a dial drop indicator. The large end was bored to size. The compound slide was then used to cut the transition between the large and small bore.

After a little cleaning and easing the edges the afternoon project is done. The hole in the small end is a little larger than it should be, but close enough to work as intended. A "little" larger as in 0.005" larger.