Track

I used flex-track to construct the track, two concentric ovals with an interconnecting "X" so that trains can follow a large or small figure-8 path in addition to ovals. The layout and locos provides the hardware to be controlled when this project/problem jumped from simulation to a "real process." The track is divided in to 16 logical blocks numbered below.

As depicted by the small gapes in the lines/track above the logical blocks are also physical blocks. Well not strictly. Initially I was thinking in terms of an old DC layout which required electrical separation for control. A DCC setup does not need that strict physical separation to define blocks.

On the other hand, several sources suggest there is an electrical reason to not have large loops of connected track powered from a single point or long lengths of track powered by DCC signals at several points. The problem is that signals from more than one source may interfere with each other at different points along the track. A signal from a single source, taking different length paths along the track to a point, can also cause interfere. Also locations farther from a connection may have a loss of power due to the resistance presented be the track and connections.

The same sources also recommended that switches be isolated and "fused" against derailment shorts. Again I think this is more of a DC concern than a DCC problem. ~Longer discussion under Switches.~ But isolating the switches does break the layout into sections avoiding any ringing of the DCC signal around the track.

The bottom line:

- Blocks 12-13, 2-3, 5-6 and 15-16 are not physically separated.

- Blocks 9 and 10 are each physically/electrically connected to the crossover in the middle of the "X".

- The four sets of three switches are each electrically connected to each other and separated from the surrounding track (more or less).

- Blocks 7 and 8 are each isolated from the surrounding layout and discussed in detail below.

Block 14 is physically and electrically isolated. The DCC signal for this block can be switched between 'Main Opt track' and 'Programming track' with a DPDT switch mounted under the layout. This provides easy access to the Programming mode of the DCC Base Station. Temporary (for the last year) labels are on the fascia of the layout.

Block 14 is also mapped as the Parking Lot/Staging Yard. As the Staging Yard there are four additional sensors and logical blocks defining four parking places for the locos.

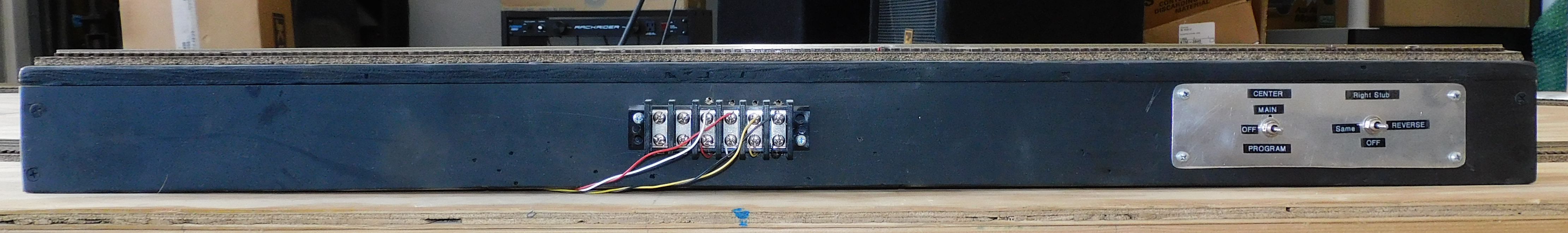

Also have a short test track that I played with while getting the layout built and running. The track is two 9" straight track sections in the middle between two 4.5" isolated stubs to keep locos from flying across the workbench. The terminal block makes easy connection to the Main Opt track and Programming track outputs from a Base Station - Arduino/Motor Shield.

DCC signal to the center and right sections of the test track are switchable. Not sure what use all of the options are, but I wanted to build the test track once.

Wiring with two on-off-on DPDT switches is straight forward.

I did use the test track to program/address the locomotives and play with the different setup options.