Knobs for Mill X/Y locks

The handles to lock the table in the X axis are too long. If I don't remember to check their position every time I move the table, the handle can (has) jammed against the vise, bed or something bending the screw.

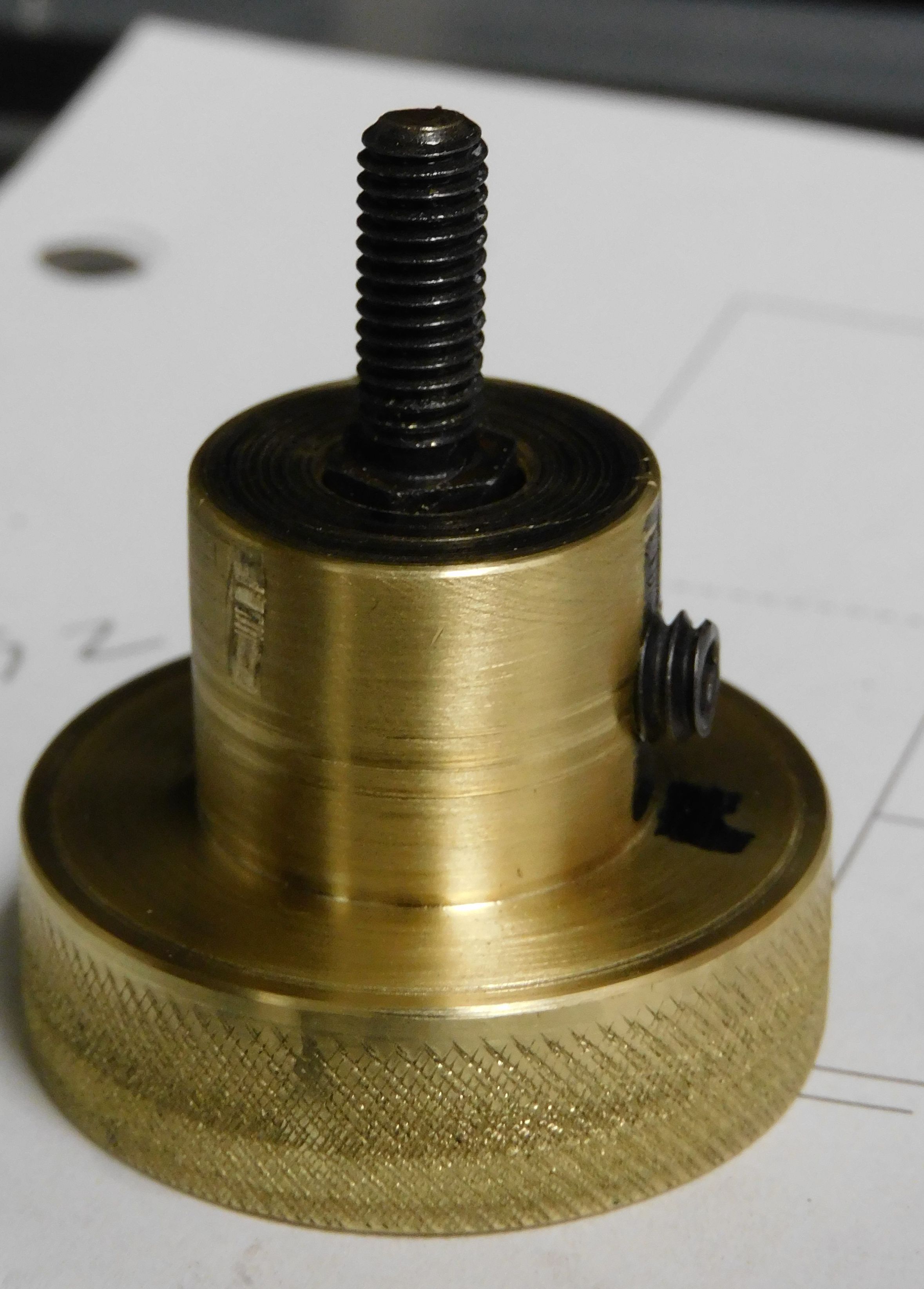

My answer is taken from blondihacks.com "Easy Improvements for Your Lathe and Mill" about 11:45 into the youtube video. The mod is to replace the long handle with a brass knob. I will made two knobs for the X-axis.

The first knob is a little rough. Need to practice the knurling and find shorter set screws. As you can see, I use a Sharpie for layout. Quick, easy and cheap. Works fine and last long enough for a simple cut or to mark a hole.

The knob just became a prototype. The shaft is too big. Fixed this on the second knob and cut the first one down.